Households and industries alike depend on reliable electrical power. To serve the diverse power needs of end users and consumers, the electrical grid is undergoing a major overhaul to upgrade a technology that is over 100 years old. The new infrastructure — the smart grid — is being developed for reliable, economic, and environmentally friendly electrical systems. A great example of equipment for the smart grid comes from ABB. Along with many other products, ABB has introduced the world’s fastest tap changer to control power transformer voltage. Electrostatic simulation, dielectric stress simulation, and high-voltage testing play major parts in their design work.

Tap Changers Control Power Transformer Voltage

In thesmart grid, transformers need to be able to regulate voltage quickly to help balance loads and generation. This is done with a tap changer that changes the number of turns in either the primary or secondary transformer winding to control the voltage ratio. While tap changers have been available for many years, new smart grid-ready tap changers feature mechatronic-based devices that enable rapid switching. ABB transformer experts in Alamo, Tennessee, recently introduced the world’s fastest tap changer, the Vacuum Reactance Load Tap Changer (VRLTC™), which boasts a switching time of less than one second. To learn more about the device, check out theVRLTC on the ABB website.

Dielectric Stress Inside the VRLTC

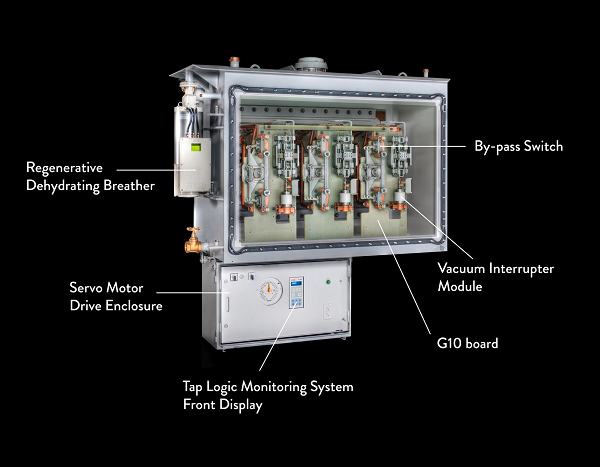

The VRLTC’s main components include switching assemblies, a servo motor drive system that provides accurate and rapid switching motion, and monitoring and control systems.

Frontal view of the VRLTC™ (Vacuum Reactance Load Tap Changer), the world’s fastest tap changer.

The VRLTC is mounted on the side of the transformer with switching assemblies placed in an oil-filled tank connected via electrodes to the transformer windings. One of the major design challenges the team faced was how to make sure that the solid epoxy barrier board that holds the electrodes connecting the transformer with the tap changer switching assemblies, as well as the G10 epoxy laminated mounting board, could withstand the dielectric stress caused by an electric potential difference of thousands of volts. With a lifetime expectancy of safe operation exceeding 30 years, testing alone wouldn’t be a practical way to study critical design parameters, such as the aging of materials and the unlimited configurations of component shape and distance between features. This is why the team turned to electrostatic simulation in COMSOL Multiphysics®.

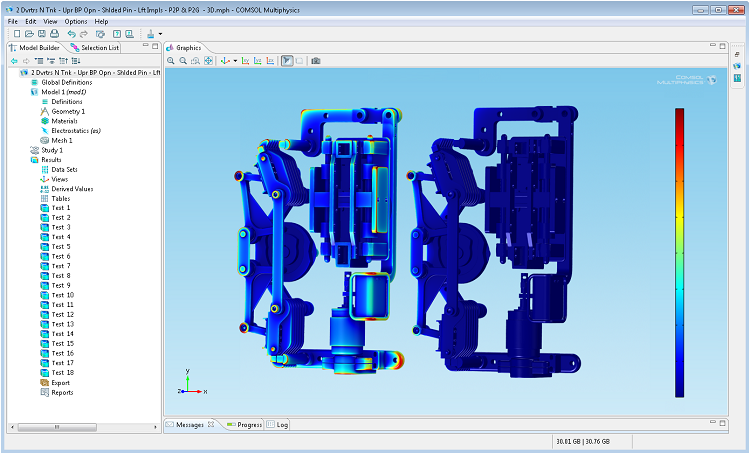

Dielectric stress simulation using COMSOL Multiphysics of the bypass switches (shown in the open position) and vacuum interrupter assemblies when applying a voltage across two adjacent phases. The assembly on the right is grounded.

Electrostatic Simulation and Testing

One of the tasks involved the G10 mounting board that holds the by-pass switches and vacuum interrupters. A problem prior to starting the simulation, however, was how to prepare their large Creo™ Parametric CAD assembly, which contained over 500 parts, for simulation. Here, ABB researchers used the LiveLink™forCreo™ Parametric to establish a bidirectional link between COMSOL and Creo™ Parametric, enabling full associativity of the geometry representations in the programs. By linking their CAD software with COMSOL, the team was able to run design iterations and modify the board configuration to maximize the predicted lifetime of the VRLTC.

Rigorous testing of the tap changer design was conducted in the ABB high-voltage lab. These tests determined the upper limit of the design’s dielectric strength. Comparison of experimental results from lightning impulse as well as 60 hertz high-voltage stress with simulation results show an excellent match. This validation of the simulation data with experiments is important for achieving confidence in the simulation strategy and tools used.

1 Million Tap Switches and Over 30 Years of Operation

By using electrostatic simulation and testing, ABB was able to optimize the design of the VRLTC and can reliably deliver 1 million switching operations that are proven to last for over 30 years. Learn more about this remarkable project by reading the article “Dielectric Stress Simulation Advances Design of ABB Smart Grid-Ready Tap Changers“. You can check out this article and many more about electromagnetic simulations by reading the 2013IEEE Spectruminsert,Multiphysics Simulation.

Creo is a trademark of PTC Inc. or its subsidiaries in the U.S. and in other countries.

Comments (0)