By design, heat exchangers transfer heat from one source to another. When analyzing the efficiency of this heat transfer, it is important to consider the impact of the system’s dimensions. Simulation offers a simplified approach to testing the performance of various designs. With simulation apps, you can now bring this power into the hands of those who are not simulation experts. Let’s get started by exploring the Concentric Tube Heat Exchanger Dimensioning Tool demo app.

The Concentric Tube Heat Exchanger: A Simple and Classic Design

With its simple design and ability to operate under high pressures, the concentric tube heat exchanger is a valued resource in many industries for a range of purposes, from food preparation to material processing. In this type of heat exchanger, a pipe is placed inside another pipe, with cold fluid traveling through the inner tube and warm fluid traveling through the space between the inner tube and outer tube. These fluids can flow parallel to one another or they can run in counterflow. While flowing through the system, heat from the warm fluid is transferred through the inner tube to the cold fluid.

Like for other heat exchanger configurations, dimensioning quantities are a key indicator in the behavior of a concentric tube heat exchanger. By computing these quantities, engineers can see how efficient the system is at transferring heat as well as how to improve the design to optimize the process. Simulation saves many steps in this analysis by testing different dimensions in a virtual setting. As different design schemes are developed, the designers and manufacturers behind the heat exchanger will turn to you — the simulation engineer — to run their simulations. This can, of course, be a rather time-consuming process, as the design can go through numerous minor modifications before the optimal configuration is achieved.

With the Application Builder, you can now take the physics and functionality behind your model and make it available in an easy-to-use simulation app. Once you have customized the app’s layout to meet specific design needs, it can be shared with your colleagues and customers, who can then run their own simulations. Extending the scope of simulation capabilities not only establishes a more integrated workflow, but it also enables you to take on more simulation projects.

To demonstrate how you can set up a simulation app that determines the optimal dimensions for a concentric tube heat exchanger, we have created a demo app, available for download via COMSOL Multiphysics and the onlineApplication Gallery. I will introduce you to our Concentric Tube Heat Exchanger Dimensioning Tool demo app here and if you want to take it for a test run, feel free to download the files afterward.

A Dimensioning Tool with an Extensive Reach

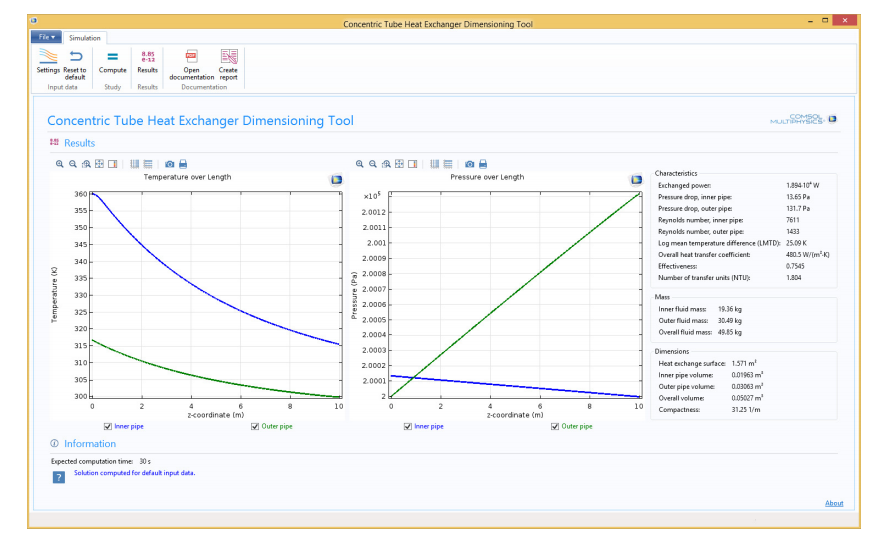

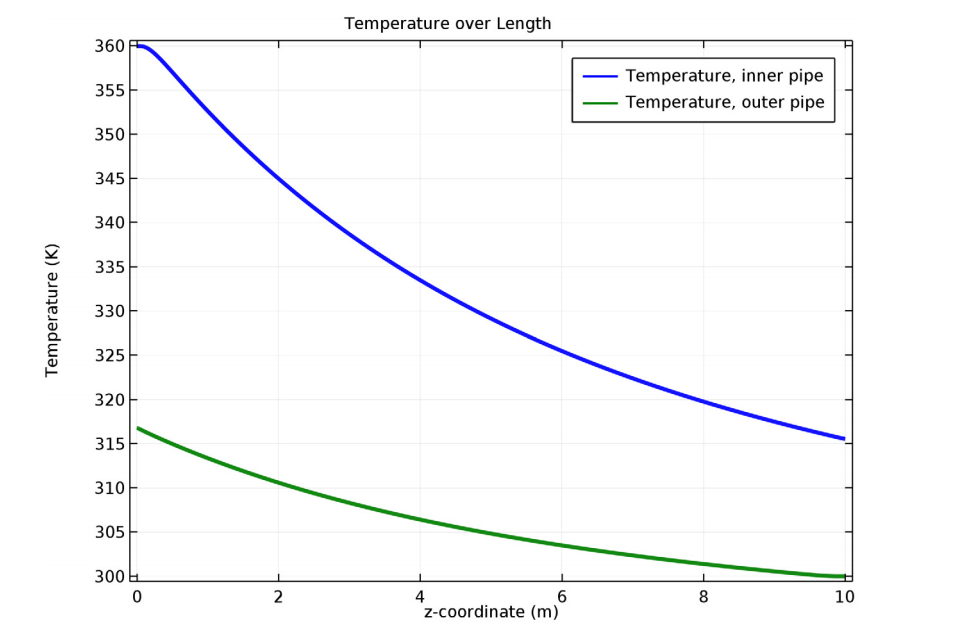

The concentric tube heat exchanger demo app is based on a 2D axisymmetric model in which two rectangles are revolved to build the pipes. To solve the flow in each pipe, a laminar or turbulent formulation is used, providing temperature and pressure profiles for both the inner and outer pipes. The results below show the profiles for the default operating parameters within the app.

On the left: Temperature profiles for the pipes. On the right: Pressure profiles for the pipes.

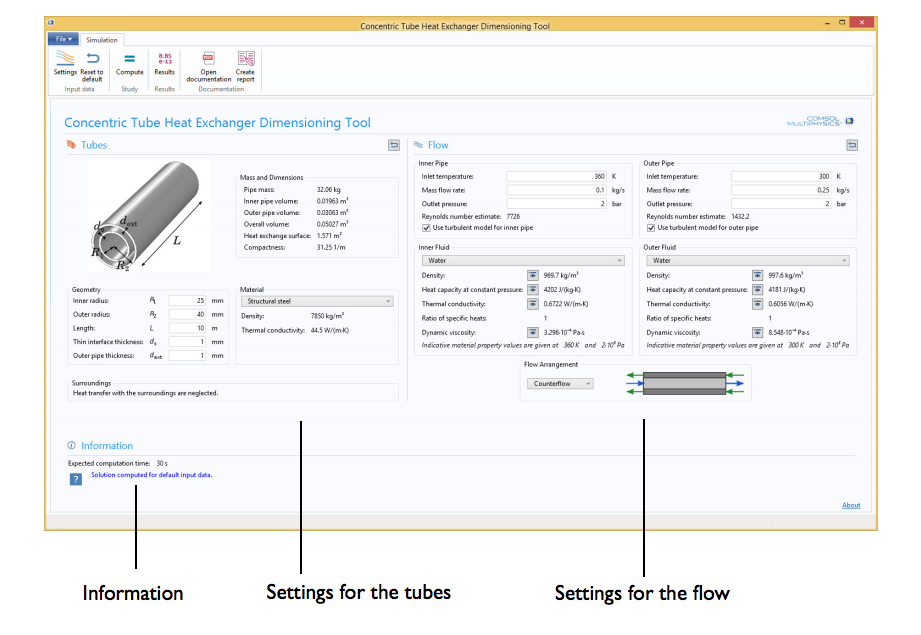

Our demo app is customized to allow app users to modify the heat exchanger’s pipes as well as the fluids. Whereas textbook formulas rely on several assumptions, this app can account for a variety of parameters, from the temperature dependence of fluid properties to the different thicknesses of the inner and outer pipes. Using the app, however, remains as simple as applying a textbook formula. The app user simply needs to enter the particular parameter values and, with just one click, they will have their outputs.

When building your own simulation app, you can personalize the user interface to best fit the needs of your analysis. Customizing your app allows you to include only the information that is important to your specific design, creating a more simplified user interface.

Learn more about building and customizing a simulation app in this blog post: “How to Create a Simulation App: Horn Antenna Demo“.

Upon opening the heat exchanger demo app, theSettingspanel initially appears. Within this panel, app users can change the geometrical parameters, operating conditions, and material properties of the heat exchanger’s tubes.

TheSettingspanel for the concentric tube heat exchanger app.

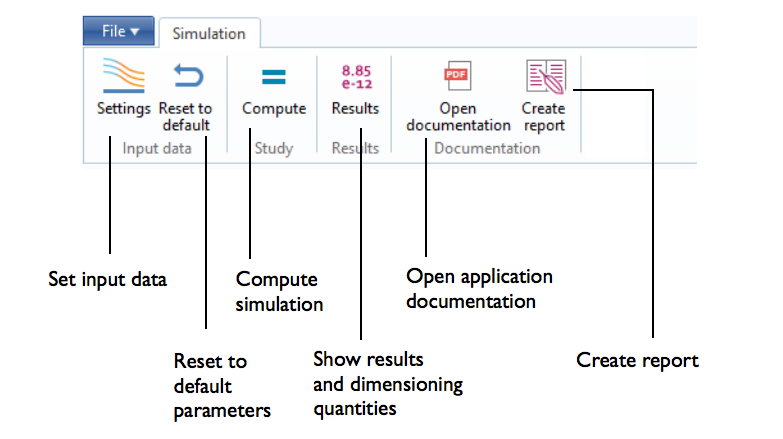

At the top of the application window, there is a ribbon featuring a series of buttons that can be used to shift between different panels. The panels include options for configuring the simulation as well as showing the simulation results. This intuitive format allows app users to easily navigate through the interface, moving from one panel to another.

Ribbon at the top of the application window.

Once computed, the app displays the temperature profile and several other quantities. These quantities include the log mean temperature difference, the overall heat transfer coefficient between the two pipes, the effectiveness ratio of exchanged heat flux to the maximum possible flux, and the number of transfer units ratio of the overall heat transfer coefficient to the minimum rate of heat capacity.

You can create simulation apps to package results in a simplified format that can be easily understood by other people involved in various stages of the design and manufacturing process. The screenshot below shows the simulation results for the demo app, available in theResultspanel. We have also configured the UI of this demo app to allow users to access the results by clicking on theResultsbutton at any point in time.

Simulation results.

It’s a Simulation Revolution

Simulation apps are changing the scope of simulation, extending its capabilities to a wider user base. By turning your own model into an app, you can establish a more efficient approach to simulation, empowering others in your organization to run their own simulation tests. You can use the demo app presented here as a foundation for building your own heat exchanger app, tailoring the configuration of the heat exchanger — and the app’s layout — to reflect your own design needs.

Download the Demo App

- Explore the inner workings of theConcentric Tube Heat Exchanger Dimensioning Tooldemo app

Comments (4)

George Northfield

May 16, 2016Hello,

Very nice application, thank you for posting. I have one question concerning the application. I am calculating an air-air counterflow heat exchanger – how can I remove or change the upper limit of inlet temperature, as it is not possible to set values only in the range 274.15K to 372.15K.

Best regards,

George Northfield.

Bridget Cunningham

May 16, 2016 COMSOL EmployeeHi George,

Thank you for your comment.

For questions specific to your modeling work, please contact our support team.

Online support center:https://www.comsol.com/support

Email:support@comsol.com

Best,

Bridget

David Zerkle

March 4, 2020Hi Bridget,

Do you have a step-by-step guide on how to build this app? I am particularly interested in how you allow for material ID specification for different domains.

Thanks

Dave Zerkle

Svein Hellesø

November 13, 2023Hi.

Have the results from this model been checked and verified against published experimental data?

Or is the physics modelling (heat transfer in circular tube with forced internal flow) been verified in other models?

Best regards,

Svein M. Hellesø