Technology and mechanics enthusiasts might agree that engines are very cool — and they also know how fussy they get when running into cooling problems. When it comes to aircraft propulsion, overheating is not an option. Most planes can’t fly safely without an engine, so why run the risk of overheating? While current engine designs limit that risk using clever cooling systems, another path to solve this problem would be to design more energy-efficient engines, exempt from excessive heat release. Let’s have a look at modeling heat transfer in a turbine stator blade, as well as discuss the evolution of aviation propulsion.

Modeling Heat Transfer in a Turbine Stator Blade

Axial turbomachines, commonly found in aircraft engines like turbojets or turbofans, typically incorporate sequential pairs of rotating and stationary blades, calledstages. The turbine located downstream of the combustion chamber is usually made of one or a few stages. It’s designed to turn the intense heat and pressure contained in the exhaust gases into both thrust and torque power. The former is provided by high-momentum gas exhaust through a nozzle, while the latter is used to make the turbomachine rotate around its shaft. Both rotating and stationary blades, also referred to asrotorandstatorblades, must be able to endure the extreme pressure and temperature conditions within the turbine. A compressor bleed air system, distinct from service bleed air, provides cooling airflow through internal ducts to reduce these thermal stresses and control blade deformation.

In the “Modeling Heat Transfer in a Turbine Stator Blade” video below, we evaluate the displacement, temperature, and stress in astator blade modelusing theThermal Stress interfacein COMSOL Multiphysics.

Aircraft Engines Powered by Jet A

Even though we may be at the dawn of sun-powered flight andelectric aircraft propulsion, most of the engines used for both commercial and military aircraft propulsion rely on so-called jet engines, powered by liquid fuels — mostly a variety of refined oil known asJet A. There are many reasons to use this particular kind of fuel, but the most important are as follows:

- Specific energy and energy density

- Jet A contains a lot of energy per unit mass, but also per unit volume, making it possible for a given aircraft to fly more passengers or cargo, and over longer distances, without bulky tanks required in natural gas-powered airplanes.

- Safety

- Even though it’s dangerous under certain conditions, its normal operating conditions are relatively safe compared to most kinds of fuel.

- Efficiency

- It’s an ideal heat source forgas turbines, which turn the heat generated in a combustion chamber into mechanical and propulsion power used in many jet engine types (turbojets, turbofans, turboprops, and so on).

The Rule of Gas Turbines

Those three advantages of Jet A powered engines have enabled technological refinements and cost optimization that have set sharp technical and economic standards ruling aviation propulsion. Any new type of aircraft engine would have to match or exceed these standards in order to compete successfully against gas turbines. The recent advances in turbine efficiency, performance, and fuel economy have been driven by the need for sheer performance enhancements (supersonic or transonic cruise, heavy load transport, extended range operations); and by rising oil costs and the advent of relatively expensive — but more environmentally friendly — biofuels. Due to Carnot’s theorem, which states that the efficiency of thermodynamic cycles relies on the temperature ratio between hot and cold heat sources, newer engine design relies on higher combustion temperatures.

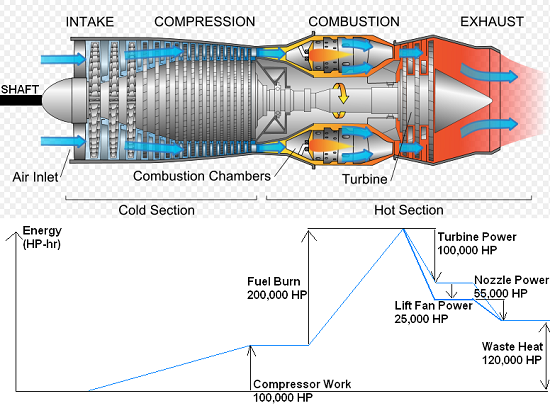

Diagram of a typical gas turbine jet engine. Air is compressed by the fan blades as it enters the engine, and it is mixed and burned with fuel in the combustion section. The hot exhaust gases provide forward thrust and rotate the turbine, which in turn drives the compressor directly linked by a shaft. Shaft power is roughly half of the heat generated by combustion, while propulsion power tops around 40% of the available heat power. Image attribution:Jeff Dahl

As we can deduce from the above image, modern jet engine turbines are subjected to propulsion gas temperatures higher than the normal limits of operations for their constitutive parts. This can be achieved only through efficient cooling of turbine parts that come into contact with the hot flow, including blades (protected by internal and external cooling) and rings.

Comments (2)

Soheil Khiavi

May 25, 2017Hi, How can I get the contact information for the author Stephan Savarese?

Thanks

Soheil Khiavi

CTO

Inventys

Bridget Cunningham

June 6, 2017 COMSOL EmployeeHi Soheil,

Thanks for your comment.

If you have any modeling questions, please contactsupport@comsol.com.