A while back, I wrote aboutpermanent magnet generatorsand how they generate electricity upon being set in motion. When browsing the papers from our conference in Bangalore, one on the topic of ultrasonic micro motors caught my eye. These motors are electromechanical in nature and instead initiate motion with the application of an electric voltage. Furthermore, these motors are miniaturized to fit a micro-scale environment.

What are Ultrasonic Micro Motors?

Ultrasonic micro motors are a type ofelectric motorthat consist of a stator and a rotor. These kinds of micro motors can be either rotary or linear, depending on how they are designed. As the name depicts, these motors are very small in size, lending themselves to applications that require low-weight and small-size components. Objects that commonly house these types of micro motors includewristwatches, cameras, and micro robots to name a few. The motors ensure high torque despite their microscopic dimensions via inverse piezoelectric effect. To add to their appeal, they are also fast, economical, and reliable. So how do they work?

The Science behind Piezoelectric Ultrasonic Micro Motors

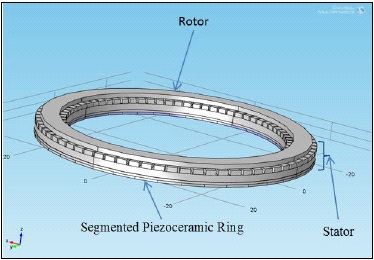

A piezoelectric ultrasonic motor consists of a segmented stator ring made out of an appropriately polarized piezoelectric motor. A rotor sits on top of the stator. When a carefully chosen electrical voltage is applied to the stator, it vibrates at ultrasonic frequencies thus generating a traveling wave. This traveling wave in turn drives the rotor. Sort of like the hands of people at a concert enabling someone to “surf the crowd” by pushing his body forward.

Piezoelectric ultrasonic micro motor. Image courtesy of Parul Patel and Premila Manohar of M S Ramaiah Institute of Technology, Bangalore, India.

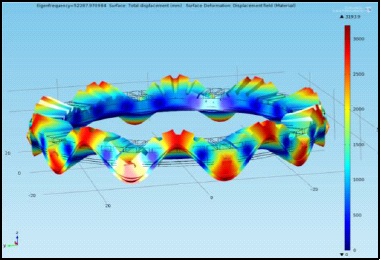

In a paper presented at our conference in Bangalore, Parul Patel and Premila Manohar show you how you can design and simulate apiezoelectric ultrasonic micro motor. The shape of the stator affects the output frequency (vibration) which in turn affects the movement of the rotor. Hence, design and analysis of the stator become critical. The researchers used COMSOL Multiphysics to analyze the mechanics and dynamics of the stator. Below is the model of their desired stator shape for putting the rotor in motion:

The stator shape producing 52.28 kHz. Image courtesy of Parul Patel and Premila Manohar of M S Ramaiah Institute of Technology, Bangalore, India.

To learn more about their research, download the paper “Design and Simulation of Piezoelectric Ultrasonic Micro Motor”.

Comments (0)