Analysis of the Stress and Load Distribution of an Assembled Screw Including Threaded Contact

There are different possibilities to simulate a bolted joint. If only the connection of parts in an assembly with the stress distribution and surface pressure between the components without the bolt itself is of interest, the thread of the bolt is omitted and only the effect of bolted connections on an assembly is calculated. Here in this work, the thread of the screw is included because the thread contact pressure besides the stress distribution is of great interest to analyze the screw itself. In accordance with VDI Guideline 2230 Sheet 2, simulations are performed here according to model class IV as the most accurate and demanding model class.

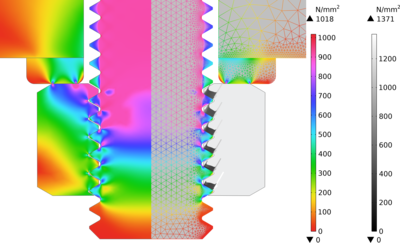

The goal of this work is to determine reliable results of the stress and contact pressure distribution of a bolted joint using studies that are as accurate as possible in terms of material and geometry. For this purpose, a bolted joint including geometric details is considered. A 2D-axisymmetric view of the bolt opens up the possibility of very finely meshing the system and also simulating it in other respects with very high accuracy. Material nonlinearity is considered. The nonlinearity is implemented with a bilinear model of the stress-strain curve using the plasticity-subnode in the Structural Mechanics Module in COMSOL Multiphysics®. Comparisons are made with geometrically simplified threads to show the importance of geometrical details for the accuracy of the simulation results. These and linear elastic studies for comparison show even higher notch or stress concentration effects. The most probable locations of mechanical failure of a bolted joint, namely the fillet of the first thread and the transition to the bolt head, are shown. All mechanical contact pairs are considered with the highest possible accuracy using the Lagrange method available in COMSOL Multiphysics®. A rather uneven contact pressure distribution at the washer on the bolt head is found. The load distribution on the threads simulated in this work is more uniform than others have determined. Additional studies with other shapes of nuts and modified threads are conducted to identify ways to equalize the thread pressure distribution.