Gas Treatment by Induction Heating: Process Evaluation via Homogenized Modelling Approach

Induction heating (IH) [1] is an electrically driven process useful for decarbonization of the industry. It can be used for electrification of chemical processes to replace traditional heating with gas burner and avoid CO2 emission. This kind of process can be used to heat efficiently the gas flux at the desired temperature. The main advantage of IH is to generate heat directly into the reactor at the surface in contact with the gas phase. It is also possible to enhance some specific chemical reaction by selecting an active substrate [2,3,4]. The use of a specific electrically conductive material which is heated directly by induction seems to be a promising route for several industrial application based on research with small lab scale reactors [3].

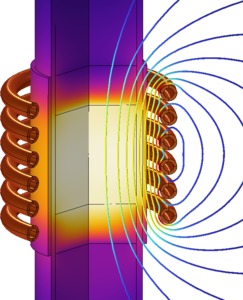

The process is constituted by a gas flux passing through the conductive substrate maintain at a constant final temperature by direct induction heating (Fig. 1). The gas is recovered at the exit with or without formation of gas by product depending on the objective of the heating process and temperature: presence or not of chemical reactions. One key parameter to estimate first is the induction efficiency: ratio of Joule power transferred to the material to the total delivered electrical power. Physical properties of the material (electrical and thermal conductivity) and its evolution with time and temperature are not easily available. Modelling description with stepwise approach give tools to define the physical and chemical principles of such processes and guidelines for experimental device improvement and upscaling. First, the AC/DC Module with the Magnetic Fields interface and a frequency domain formulation is used to estimate the power distribution in the material with a simplified homogenized modelling approach in the COMSOL Multiphysics® software. The material is considered first as a dense material with an equivalent effective electrical conductivity. A parametric study is realized to estimate the induction efficiency as a function of the conductivity or a normalized ratio rc/delta (radius of material versus electromagnetic skin depth). Such curve gives guidelines for process optimization to obtain a maximum induction heating efficiency (> 90%) through a fine tuning of the process parameters. The electrical conductivity is extracted from experimental process data by using correlation with modelling results. Then, a coupling with heat transfer is realized by considering radiative losses at the external surfaces and the heat convection term due to the gas flux. Another heat source terms can be added if we consider the power needed by an endothermic reaction. Specific curves are implemented to approximate evolution of parameters vs temperature (physical properties of porous material, evolution of power need if we consider chemical reaction…). The coil current is tuned to maintain the final desired temperature (Fig. 2).

下载

- Dumont_5621_poster.pdf- 4.02MB