Influence of the Complexing Agent on the Throwing Power during Silver Electroplating

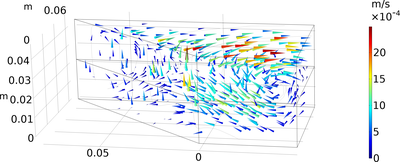

The throwing power is an important criterion for the industrial use of an electrolyte in electroplating applications. Using the Electrodeposition Module and COMSOL Multiphyiscs® it is possible to simulate the thickness distribution for various electroplating geometries. For a realistic description of an electrochemical deposition the electrical field, chemical reactions in the electrolyte and on the surface and the mass transfer of the ions must be considered. For this purpose, the CFD Module is combined with the Tertiary Current Distribution and the particle transport via Nernst-Planck. For the application considered in this contribution a further challenge is the complexing of the silver. COMSOL Multiphysics® offers the modeling of a chemical equilibrium reaction for this, however the use of it impairs the convergence of the model. For 2D simulations of an experimental setup (Hull cell) it could be shown that the complexing agent has an influence on the deposition. For the industrial application significantly matters only a very strong complexation of the silver ions. To validate the simulation 3D calculations were performed under the assumption of natural convection because of density gradients of the electrolyte in front of the electrode. The Boussinesq approximation results in a circular flow with a continuous upflow of low concentrated electrolyte at the cathode, which explains the decreasing of the layer thicknesses with the height on the Hull cell plate. Overall, there was a good correlation between the experimental and simulated thickness distribution on the cathode. The validated model can now be applied to various geometries and industrial applications to optimize the process parameters.

下载

- Baumer_5481_poster.pdf- 2.91MB