Lubrication of industrial contacts: accounting for roughness contribution with a reduced order model

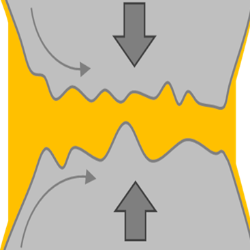

While the modelling of smooth concentrated contact lubrication has been achieved a few decades ago [1], the engineer is often left with no other option than to neglect many aspects of real-world contacts. Among these aspects, the contribution of roughness in lubricated contacts is computationally too expensive most of the time. However, a comprehensive homogenization method allows for the mathematical separation of the contact scale from the roughness microscale, enabling them to be solved in distinct domains in a fully coupled manner [2]. This approach enables quantitative predictions in contrast to explicit solutions, but it remains computationally demanding. In this presentation, the authors demonstrate the feasibility of reducing the parametrization of roughness scale equations and interpolating their contribution using a method based on Gaussian Process Regressions. This method allows for solving the microscale contribution through pre-calculations and using them in a lubricated contact model. This is a proof of concept which establishes the feasibility of the method. It constitutes a milestone toward the resolution of rough contact lubrication within an industrially feasible timeframe.