Xi Engineering Consultants Ltd.

Address & Contact Information

If you have any questions about the services we offer or if you would like to have a chat with one of our engineers, then you can send us an email or give us a call. We are always happy to help.

Xi Engineering Consultants Ltd.

Codebase, Argyle House

3 Lady Lawson Street

Edinburgh

EH3 9DRB

United Kingdom

Tel:+44 (0)131 290 2250

Email:hello@xiengineering.com

Web:xiengineering.com

Who we are

Xi Engineering Consultantsis a specialist engineering consultancy which excels in solving complex engineering problems. Our team specializes in the complex modelling, measurement and analysis of dynamic systems. Thought the origins of the company are in the fields of noise and vibration, we work extensively beyond these areas. We have a broad approach to problem solving and actively engage our expertise over a wide range of engineering disciplines and industry sectors.

Industries we specialize at:

- Building, Structures & Planning

- Consumer Product

- Industrial

- Medical

- Energy (including Renewables)

- Transportation

We work with clients all over the world including Europe, North America, Asia and Africa and our work is often presented at international conferences and published in peer-reviewed articles. We have won several awards for our work throughout the years and some of our work on electrostatics and acoustics has also been published in NASA Tech Briefs.

What we do

Our diverse experience means we are proficient in applying design optimization to a variety of sectors, across all physical scales. Our team features a strong multidisciplinary group of specialists, allowing us to work with a multitude of COMSOL modules.

Our expertise includes:

- Structural dynamics, vibration, fatigue and robustness

- Multibody dynamics used for example in drivetrains

- Acoustics

- Electromagnetics used for example in electrical motors and generators

- Electrostatics used for example in touch screens and speakers

- Piezoelectric and other MEMS devises

- Computational Fluid Dynamics

With a strong reputation in solving problems presented by our clients, our approach is to lead the client through the process from problem and uncertainty through to solution and client satisfaction.

We pride ourselves on delivering economic benefits to our clients and have gained a powerful reputation for our innovative and collaborative approach. With applied ingenuity, we go the extra mile and assist our clients from the idea-generation stage to detailed implementation.

Core Services

Simulation- We use science to deliver accurate models which represent the real world and help to make them commercially viable. Our team can help to accelerate your design process by simulating your system and using the model as a robust test bed for various scenarios.

Measurement- We have the expertise and knowledge required to measure devices, machines and structures across all sizes and scales, from wearable technology to wind turbines. We often combine our Measurement and Simulation services to validate numerical models with real world data. This provides an even more powerful and accurate decision-making tool for our clients.

R&D Partner- Our pioneering R&D team can help design, develop, accelerate and confirm your next product. We can provide full project support and help you through the development cycle all the way to taking your product to market.

Expert Witness & Due Diligence- We have experience of working with a diverse range of stakeholders, including the government, Ministry of Defence, local authorities as well as corporate clients.

Planning & Environmental Impact- We help our clients through all phases of planning projects. From project design through to planning sign-off and consent, our team are well equipped to be able to assist you.

Why choose Xi

Our team’s capabilities range from small-scale consumer products to large machinery, with completed projects including everything from robots and high-end electrostatic headphones to critical equipment on wind farms and aircraft carriers.

Xi uses advance simulation techniques to help our clients understand the complex physics behind their projects. At Xi we believe that simulations are most useful when they are tied to the real world therefore, we use physical measurements to validate our models. It is important to us that our engineers "get their hands dirty” by becoming, where possible, familiar with the physical product in order to provide you with the best possible simulations.

To give our clients technical understanding and insight we have athree phased approachwhich can be used to underpin some or all of the aspects of your project. Get in touch in order to learn more about how we work and the benefits we can bring to the table.

Featured Modeling Projects

Product Development

Headphone Speaker Optimization with Warwick Acoustics Ltd.

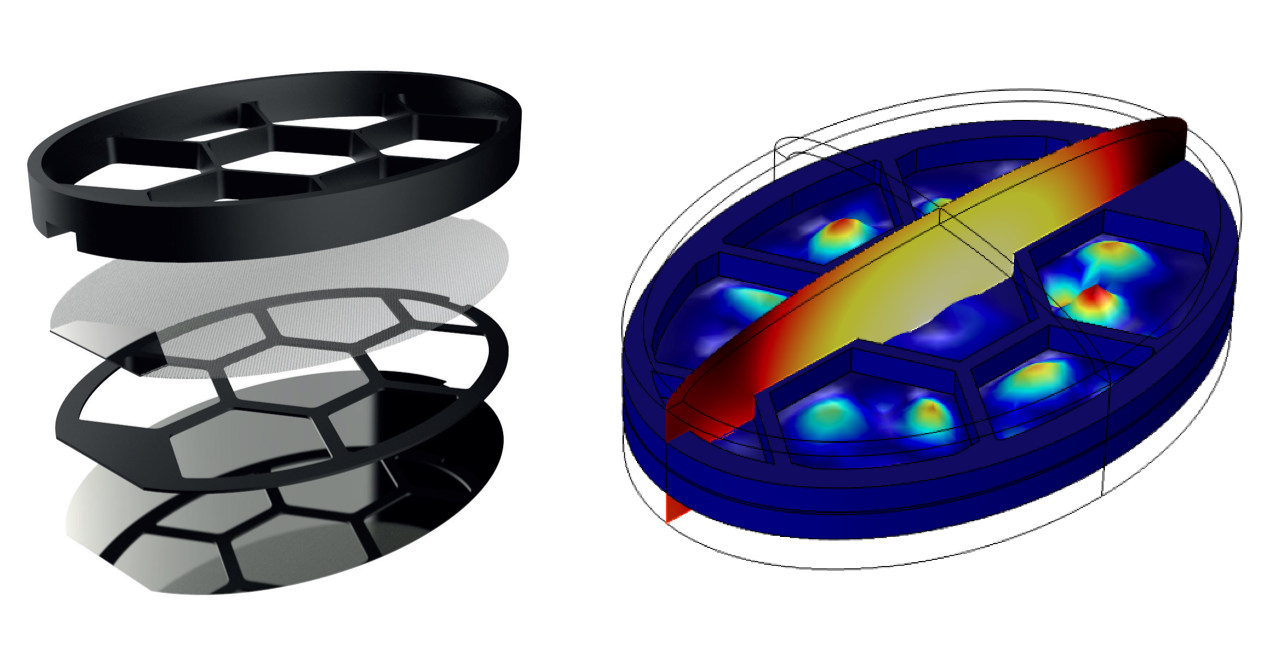

Using the COMSOL Multiphysics®software, we helped Warwick Acoustics. optimize their headphone geometry and speaker design. To do so, we modelled the relationship between the MEMS components and the speaker's acoustic response as well as their interaction with the surrounding headphone geometry. Our team also developed fully coupled interactive COMSOL®apps and made them available to Warwick Acoustics using the COMSOL Server™ product. This allowed them to virtually test proposed design modifications without the cost of manufacturing prototypes. In this project, we used the Structural Mechanics, MEMS, and Acoustics modules.

"The team at Xi Engineering has been superb; they have deep expertise and helped to unpick the complexity of our product.”

― Martin Roberts, CEO of Warwick Audio Technologies, Ltd.

Acoustic Resonance Analysis of a Microphone Chamber

With the Acoustics Module, our team produced a model to analyze a new acoustic chamber design in one of our client's products. We identified the acoustic resonances within the chamber by modeling the pressure acoustics and thermoviscous effects. This analysis helped us verify that the design was of a high standard and ensured that the acoustic chamber did not interfere with the microphone's operation.

Structural Behavior and Operational Response

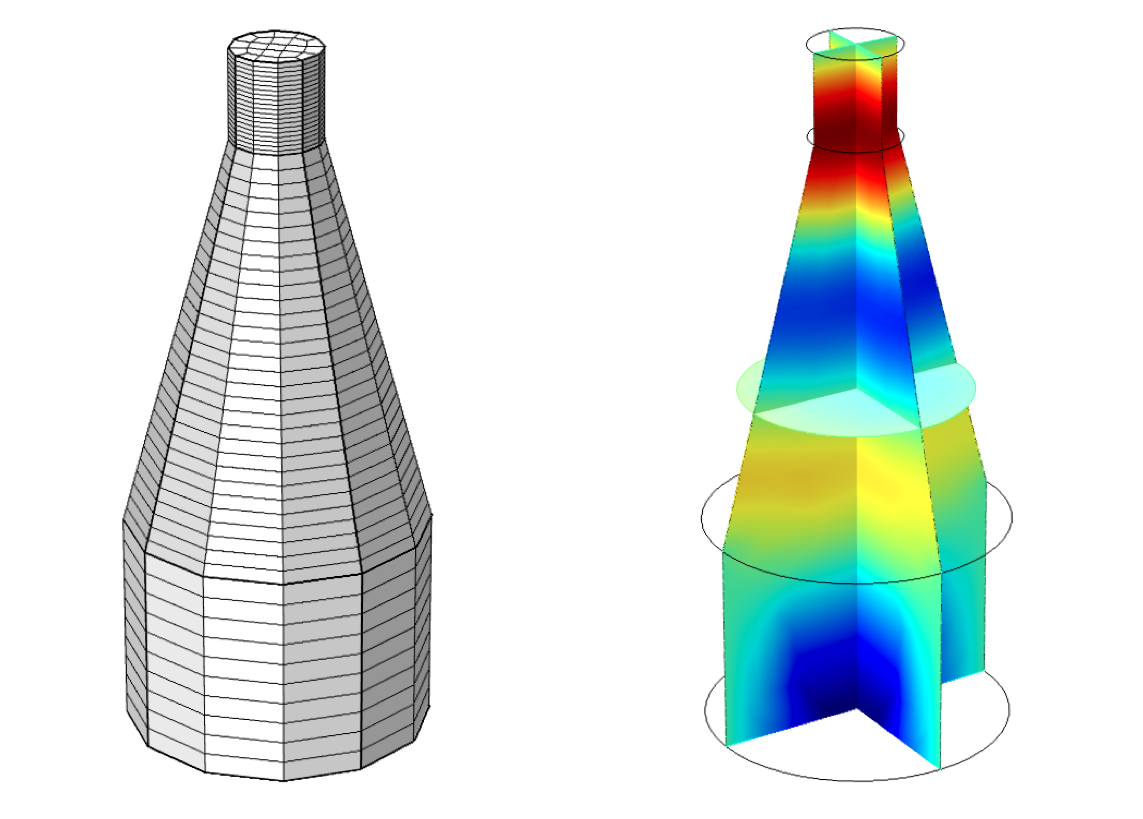

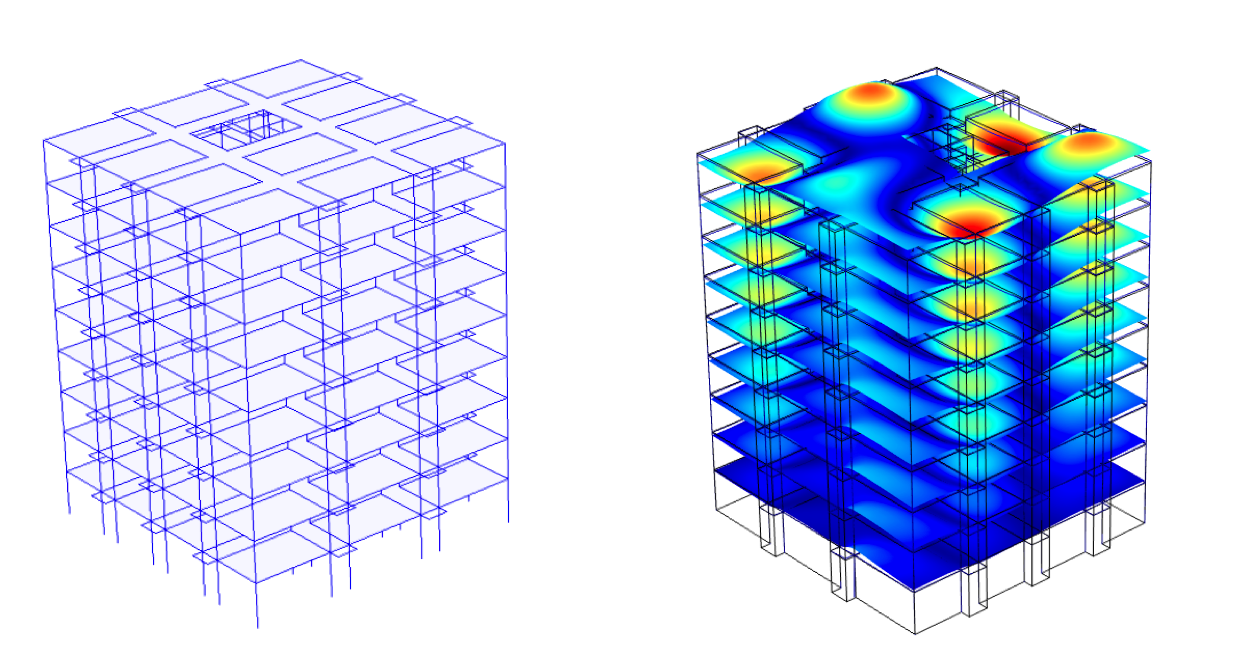

Modeling a Building's Structural Dynamic Response to Determine the Optimum Location for Sensitive Lab Equipment

Using the Structural Mechanics Module and beam and shell elements, our team developed a model based on engineering drawings to look at a building's dynamic response. We used our model to investigate the vibration characteristics of the building and determine the best location to place a lab with sensitive equipment. The analysis accounted for the frequency response from people moving within the building, external wind loading, and even a simulation of a fire evacuation scenario.

"I had a very good experience working with Xi. Donald in particular was excellent at briefing the client. He gave them a clear explanation which was very useful, it’s nice to see a company that takes the time to explain what they’re doing rather than just getting on with it…fantastic communicator. The technical report produced at the end was invaluable to us and it was delivered on time and followed up really well. I can’t really think of any improvements to be made, WYG will have some follow-up work and projects to do and we will not hesitate to bring Xi on board."

― Keith Morrison, Associate Director at WYG Group

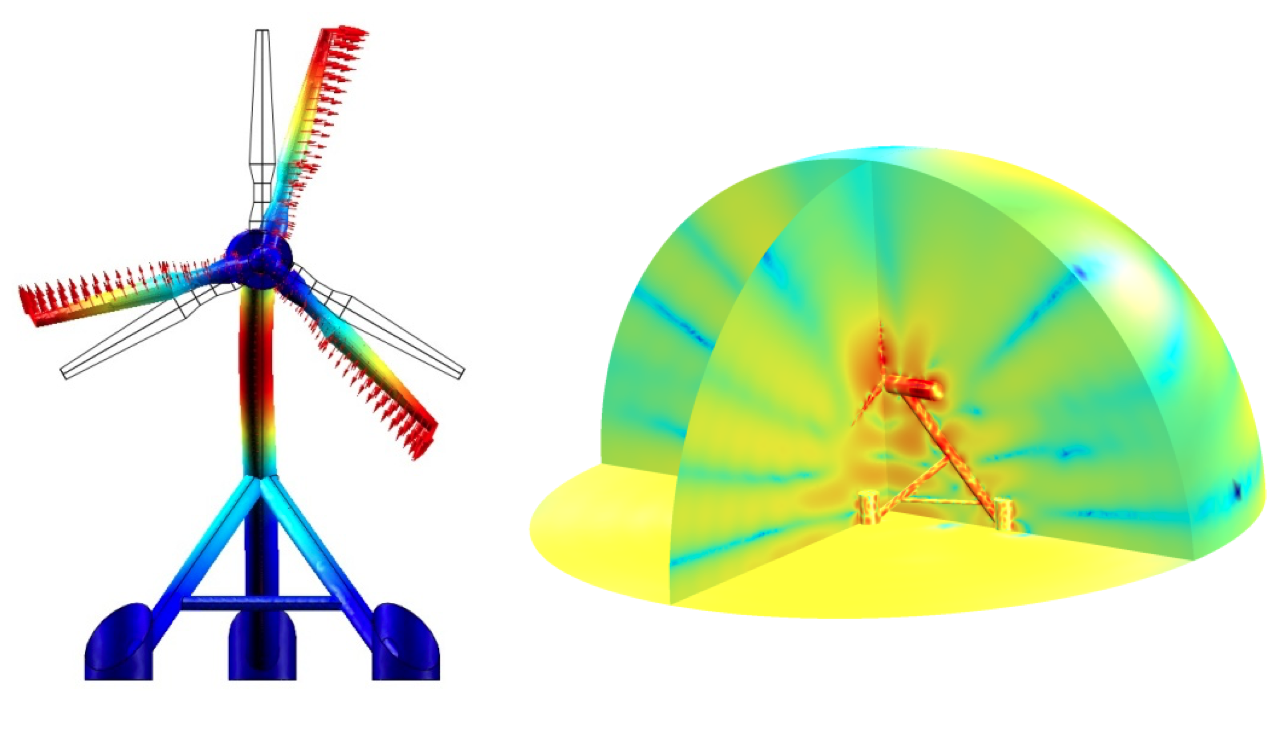

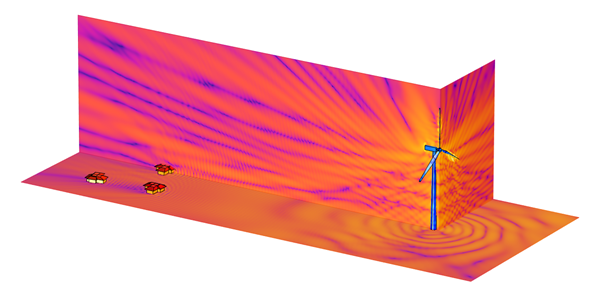

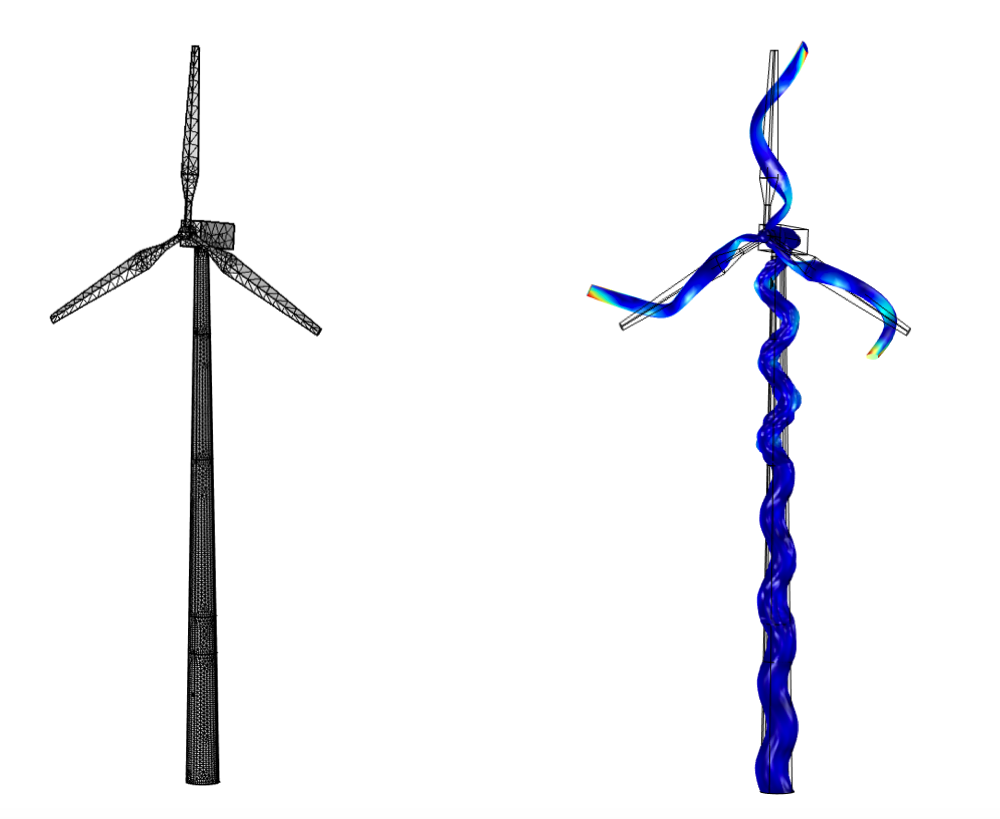

Modeling the Operational Behavior of Wind Turbines for Tonal Noise Reduction and Broadband Damping Specification

We developed a wind turbine model constrained with empirical data by using LiveLink™ for MATLAB®. The Structural Mechanics Module enabled us to determine the surface acceleration of the turbine blades, tower, and nacelle during operation. The structural model is fully coupled to either an acoustic finite element model or boundary element method model (depending on tonal frequency) and the far-field tonal noise level calculated. Through this, we created a model to design and optimize the installation of broadband dampers, which reduce the tonal noise emissions from a turbine in a cost-effective manner.

Design Review and Fatigue Analysis

Modeling Operational Characteristics of the HS1000 Tidal Turbine to Predict Operational Behavior in a Marine Environment

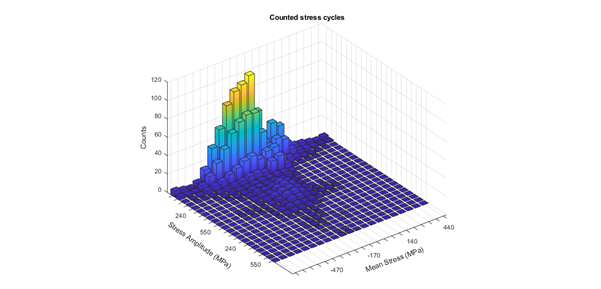

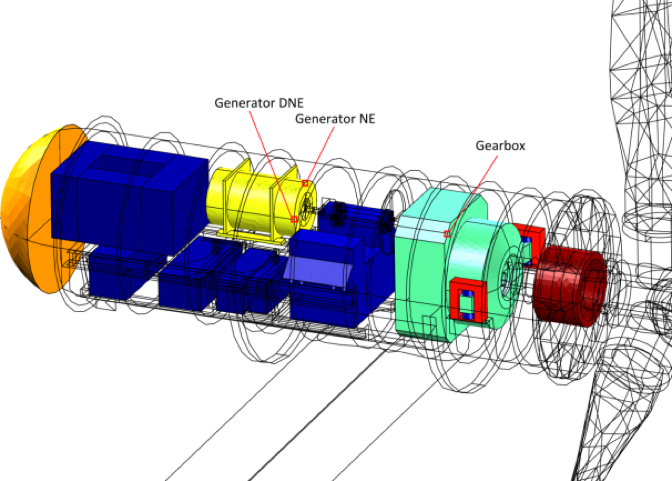

When working alongside ANDRITZ HYDRO Hammerfest, we helped to develop their HS1000 and 1.5 MW tidal turbines and make the turbine fit for use in marine environments. For our studies, we used the Structural Mechanics and Acoustics modules. To determine the operating vibration levels and frequency response of the surrounding structure, our team analysed the system's drivetrain. With modelling, we calculated cycle stresses and fatigue life to design out potential failure sites. We also included the fluid-structure interaction and effect of water on reducing the frequency of structural harmonics.

We used these models to determine the underwater acoustic emission of the tidal turbine and assess the environmental impact on marine species. With the modelled dynamics, we can design and optimize a condition monitoring system to give live readings on a turbine's operating conditions.

"The development of our HS1000 device is a challenging and complex engineering task. We have worked with experts in various fields in order to ensure that the very best technical input culminates in a reliable, robust, and highly advanced tidal turbine. We have greatly valued the engineering expertise provided by Xi and look forward to their continued support at this exciting stage of the development."― Michael Betschart, Engineering Manager at ANDRITZ HYDRO Hammerfest